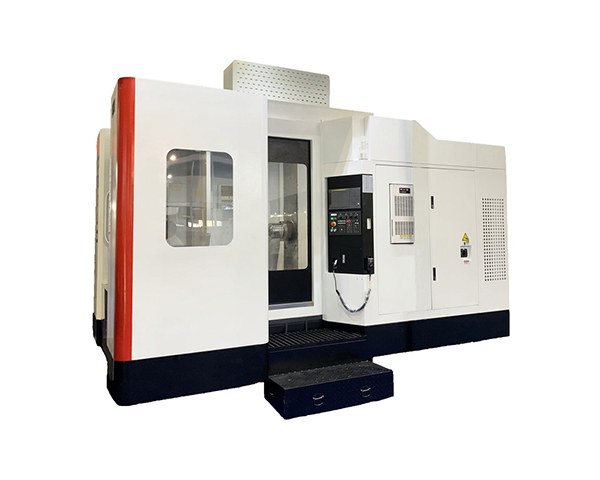

High accuracy and high performance spindle

-Direct-drive spindle speed at 12000rpm(BT40).

-The spindle is dynamically balanced for extremely smooth running.

-Spindle cooling system (opt.) removes heat efficiently and minimizes thermal deformation.

-High precision helical springs features high dynamic balance and low vibration.

High stability tool magazine

-Absolute encoder ATC system provides high stability and speed.

-Inverter prevents tool change speed from changing under different power supply frequency.

-Tool change speed can be adjustable for heavy tools.

-Auto tool change T-T 1.8 sec, 24 tools.

High precision linear guideway

-The diameter of ball screw and linear guideway used in the tapping centers of Machine Tool are larger than 1.28 times of the same industry, ensuring the maximum load capacity and extending the service life of the machine.

-Standard 3 axis with a high precision linear guideway (made by HIWIN or PMI)

Laser inspection and ball bar test

-A sophisticated laser unit is employed to inspect the three-axis accuracy.

-Including linear positioning, positioning, accuracy, pitch error, and backlash, etc.

-A ball bar tester is employed for inspecting servo accuracy, static and dynamic geometric errors.